Indicators on Perforated Metal Infill Panels You Should Know

Table of ContentsEverything about Perforated Metal Infill PanelsAbout Perforated Metal Infill PanelsPerforated Metal Infill Panels Fundamentals ExplainedPerforated Metal Infill Panels for Dummies

Infill wall surfaces are normally set up on site as individual elements that are pre-cut to length yet they can be pre-fabricated as huge panels with the cladding currently connected. The same components might be made use of for interior separating walls, yet right here the primary issues are fire resistance and acoustic insulation instead of resistance to. perforated metal infill panels.loading. A small interior pressure is made use of in the layout of interior separating walls. @&&h2@ [top]

Kinds of

The Buzz on Perforated Metal Infill Panels

infill walling @&&/h2@ Various forms of building can be used to develop infill walls that span in between floorings in steel or concrete buildings. Typically, infill walls made use of masonry or wood, yet the modern-day form of building uses light steel C areas that span in between the floorings as well as around openings. The C sections are put at a normal spacing depending upon the outside faade materials, and at a spacing which is additionally compatible with common plasterboard and sheathing board sizes. @&&h3@ [top]

Light steel framed infill walls @&&/h3@ In multi-storey framed building and construction, it is currently usual technique to use light steel infill walls to produce a quick completely dry envelope to sustain the outside cladding. The same type of building might be used as dividing or compartment wall surfaces between various components of the building. The use of light steel infill walls might be put on steel or concrete framed construction. Lightweight, rate and also convenience of installment are necessary constructional benefits that have actually brought about the fast increase in operation of this form of construction.

The light steel elements used in infill walls contains C areas and also U areas of.

Getting The Perforated Metal Infill Panels To Work

75 to 150 mm deepness that are chilly roll-formed from galvanized steel strip of 1. 2 mm thickness defined to BS EN 10346. The galvanizing( zinc layer) provides excellent longevity. The C areas are put at 400 or 600mm spacing as well as sets of C areas may be used alongside huge openings. Wall surface panels can be pre-fabricated as storey-high systems or, more frequently, are website constructed from C areas that are supplied cut-to-length. The 2nd method is commonly the only solution in remodelling applications where resistances in the initial construction have to be suited. Site constructed light steel walls in a steel mounted structure Pre-fabricated light steel infill wall panels in a steel mounted building Infill wall surfaces contain a lower' track' connected to the flooring as well as a leading' track' attached to the bottom of the floor over. This activity is vital in concrete structures, where 2 to 3 mm shortening of the concrete structure per floor can take place over time in addition to normal architectural activities. The vertical C sections are developed to extend 2. 4 to 5m in between floors, and also to resist wind loads or various other tons in flexing. The horizontal C sections above and below the windows transfer tons back to the vertical C sections. 1 or 2 layers of' fire-resistant' plasterboard( complying with BS EN 520, Type F) to the interior face offer as much as 90 minutes fire resistance to the light steel infill wall surface. @&&h3@ [leading] Light steel separating wall surfaces @&&/h3@ Pre-fabricated light steel wall surface panels Light steel dividing walls make use of similar parts to.

light steel infill walls and are used to supply acoustic separation and fire compartmentation in between occupancies or unique parts of the building. For both of these features, double layers wall surfaces are generally defined in order to achieve the required acoustic attenuation between occupancies. The structural loading for inner wall surfaces is relatively low as well as is usually considered to correspond to an inner pressure of 0. 5 k, N/m . The C areas are usually much thinner than in exterior walls( normally 0. 9mm thick )and also get some advantage of the rigidity of the plasterboard chosen the outside. Dividings are not called for to have.

acoustic or fire features and so are single leaf walls making up C areas of 55 to. perforated metal infill panels.

The Basic Principles Of Perforated Metal Infill Panels

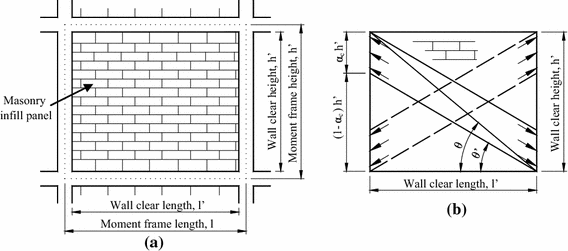

90mm deepness, depending on the wall surface height, with solitary layers of plasterboard on each side. @&&h3@ [top] Stonework image source infill walls @ & &/ h3 @. Wall surfaces built from clay blocks or concrete blocks are the typical type of infill wall surface building. However, making use of block-work infill walls has actually reduced in recent years due to the fact that it is an untidy and time consuming website operation, and also needs a large quantity of materials handling. From a style factor of view, enhancing blog posts are required following to huge window openings, as the masonry is not adequately solid to resist the high neighborhood wind loads beside these openings. @&&h3@ [top] Concrete infill wall surfaces @&&/h3@ Pre-cast concrete infill wall surface panels Concrete infill walls are typically in the kind of huge precast concrete panels that are storey high as well as commonly of a size determined by the column spacing. These large panels may be top put up or lower sustained. They usually birth onto the flooring piece

making use of a boot setup, and also are bolted back to the structure on the level above or below. Indispensable panels might be outfitted in various other products( typically concrete panels are clad in stone). Panel weights of around 300kg/m are regular, with panel widths of between 3 and 9m and height of 3. 2m. The maximum size of panel is restricted by transportation factors to consider and also crane training capacity( both on site and at the concrete jobs). 15 to 20 tonnes are regular maximum weights of precast concrete panels. @&&h3@ [leading]. Hardwood mounted infill walls @&&/h3@ Wood infill walls use conventional wood sections of 90.